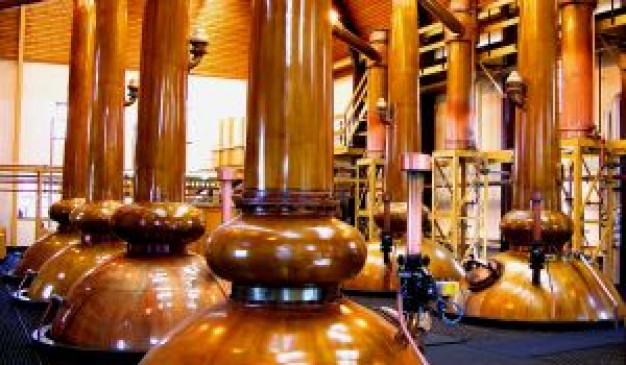

Why do copper pot stills always look so different?

Every still produces a different whiskey. Alembic stills (the ones that look like copper cauldrons with elephant trunks…) have been around since the Egyptians were using them to make perfume! The mixture of water and grain that has been fermented to create distiller’s beer is loaded into the base (cauldron) and heated to separate the alcohol from the solution through evaporation. It’s pretty simple, actually.

The boiling point of alcohol is lower than water and the rest of the mixture so that will evaporate first. The mash (fermented grains) go in at about 8-10% alcohol and come out after the first run through the still at 25-30% alcohol. That 25-30% alcohol solution that comes out of the first run is called the low wines. Whiskey gets 2 distillations. The second run through will bring that low wines’ alcohol level from 25% up to around 70% (140 proof) or more, but never over 80%. Anything over 80% alcohol (160 proof) would not legally be whiskey.

The shape and size of the still affect the flavors that make it into the final product. Often the still used to create low wines (wash still) is a simpler set up than the still used for the final distillation (spirit still). Sometimes a distillery has a larger still to strip alcohol in the first run and a smaller still to refine the spirit for the second run. There is much less volume at the end of a distillation, so unless the low wines are stored and accumulated, a smaller still will do the job. The big differences in shape and size are in the top part of the still. That’s where the magic happens.

The bottom of the pot still is usually a big pot-like cauldron shape because its job is to hold the mash and cook it. Fire heated bottoms are made thicker so they can withstand the direct heat and the scraping from agitators or rummagers (Think stirring a stew so bits don’t stick to the bottom and burn…). Most stills you’ll see now are steam heated which is a great deal safer and much more easily controlled by the distiller. The alcohol begins to evaporate and move up into the neck. Here’s where the shape of the still becomes important.

As the vapors move up, they cool and condense on the inside of the neck (it’s cooler up at the top than at the bottom) and drip back down. The taller the top of the still, the more pure the vapor would have to be to make it all the way up and over into the condenser where it will become liquid again. Taller stills give you lighter more delicate distillate. The squatter the still the more easily heavier compounds can get into your finished product. Shorter stills give you heavier spirits with more oily mouth feel. The big bulge you usually see in a still just above the pot is helpful in the heat exchange from the boiling hot base to the neck of the still. More surface area to cool the hot vapors as they leave the pot help the neck do its job better. Sometimes the neck is constricted before the bulge in the neck which calms the vapor column between the boiling mash and the neck.

The job of the neck of the still is to cool the vapors coming off the heated mash and stop unwanted compounds from making it into your whiskey. The vapors cool as they move up the neck and drip back down to the pot in a process called reflux. The copper on the inside of the neck reacts with sulfur compounds and pulls them out of the liquid. This is very important to the taste of your whiskey because, without copper, your whiskey would taste funky. This process of removing sulfur is also the reason that the copper parts of a still must be periodically replaced. Chemically breaking down the copper inside the still erodes it and thins it to where it loses its integrity. Stills don’t last forever. The lyne arm, which is the pipe that connects the neck to the condenser gets the most wear because that’s where the most aggressive alcohol vapors are.

The job of the neck of the still is to cool the vapors coming off the heated mash and stop unwanted compounds from making it into your whiskey. The vapors cool as they move up the neck and drip back down to the pot in a process called reflux. The copper on the inside of the neck reacts with sulfur compounds and pulls them out of the liquid. This is very important to the taste of your whiskey because, without copper, your whiskey would taste funky. This process of removing sulfur is also the reason that the copper parts of a still must be periodically replaced. Chemically breaking down the copper inside the still erodes it and thins it to where it loses its integrity. Stills don’t last forever. The lyne arm, which is the pipe that connects the neck to the condenser gets the most wear because that’s where the most aggressive alcohol vapors are.

The idea is to design your still to create the type of whiskey you’re interested in making. Often, companies starting out will buy what they can afford and tweak the still to fit their needs. Think of a still as a musical instrument that some people can just play with more talent than others.

An artist will adjust the way an instrument is played to get the notes they want. So it goes with master distillers…