I touched on the fact that William Lanahan & Sons were master blenders. They were also on the cutting edge of experimentation.

One of the commonly repeated tropes about pre-Prohibition Maryland rye whiskey is that “most of it was rectified.” I think that most modern whiskey drinkers have a warped sense of what that actually means. Rectification is a much older tradition than barrel aging. Yes, rectifiers often used techniques that seem odd to the modern whiskey consumer because they involved using flavorings, colorings, or additives. However, there is a LOT of false and/or misleading information out there about these techniques due to the examples of bad actors before, during, and after Prohibition that make for a good story. A few bad apples can spoil the whole crop, but these “bad rectifiers” were not the norm. We must remember that the whiskey industry was well established by the late 19th century, and bad actors did not and could not compete with the finest whiskeys on the market. Large cities like New York, Philadelphia, Baltimore, and Louisville were full of liquor firms that acted as rectifiers- meaning they operated with rectifying licenses. These businesses had warehouses where their rectifying took place and store fronts where they sold their products. The larger firms had separate warehouses and liquor stores in the downtown neighborhoods of all the major cities. Many distilleries chose to do exclusive, contract business with these rectifying firms. One might compare this practice to today’s contract distilling market (not entirely the same, but similar). A respectable firm kept their distillery sources close to their chests and maintained those relationships for decades. It kept distillers and rectifiers both in business as they supported one another. Distillers made the whiskey and the rectifiers purchased it in bulk, blended it, bottled it, and handled its distribution and sale. In some cases, the distillery and the rectifying firm were part of the same company, but it many cases (if not most), they were independent of one another. This was the case for William Lanahan & Sons. They did not distill the whiskey, but they made the whiskey they purchased their own.

Here is an excerpt from an ad for Hunter Baltimore Rye in “The Successful American,” an illustrated magazine in 1900. It describes the blending process used by Lanahans.

“The blending of whiskies is rapidly rising, if not to the level of a fine art, at any rate to the dignity of one of the exact sciences. Apparently it is a most simple process, but if it be exercised in its ideal perfection requires the keenest discrimination and the closest attention to every detail. The theory in blending is to combine in one product all the prized characteristics found in different types, but never present altogether in a single “straight” whiskey. Mixing, however, is not blending. The task is only begun when the component parts are put together. And however well matured the various constitutents (sic) may be the object of blending is practically missed if facilities be not given for the development and absorption, for the intercommunion and commingling of the several vegetable oils and volatile ethers, and for their gradual combination into one perfect and harmonious whole.

“These points are gradually finding increased recognition among blenders, and various means are adopted to attain the desired end. One device, for which Messrs. Wm. Lanahan & Son are responsible, has for its main idea the application of the well- known principles of heat and motion by perfect aeration of each and every particle to secure maturity and development, as well as a most thorough and intimate amalgamation of all the ingredients of the blend, the ingredients being standard brands of well-matured and finely developed Maryland Ryes. The apparatus designed to effect (sic) this purpose has been erected by this firm at a large expense, the receiving cisterns or vats holding 45,000 gallons of whiskey. It is in these vats that the blending is done, there being eight in number. The whiskey in each vat is subjected to ten thousand revolutions in ten hours. It is very properly claimed that this enormous amount of motion and aeration has the effect of completely removing all impurities, and that the result of this continual agitation of the whiskey is an improvement and mellowing down consequent upon the enormous evaporation that can be accomplished in no other way. The greatly renowned brandy houses of France, and the sherry houses of Spain, in putting upon the market their fine products, always offer a blend of their respective goods. The business of producing fine blends has been in existence in Europe for more than a century. while in this country it is comparatively in its infancy. The public can feel assured that they can always secure better uniformity and better matured goods, possessing more intrinsic merit, in reputable blends than in any other class of whiskies.”

The process described above was not a new or revolutionary way to blend spirits. Heat and agitation had been employed by rectifiers for many decades before this ad for Hunter Baltimore Rye was released at the turn of the century. In fact, the Bureau of Internal Revenue legally approved the use apparatuses that employed heat and agitation by distillers/rectifiers in the 1870s. A Pennsylvania distillery known as Peiffer & Richards (which later became the Meadville Pennsylvania Distilling Company) pressed the issue in 1877 through their use of the patented “Corey apparatus.” The government was forced to admit that the invention “was a useful one, of practical value and utility…” What these companies in the late 1800s understood about the use of heat and agitation (and in some cases, injection of air) was that adding differing degrees of heat to aged spirits changed their chemical composition.

Certain undesirable flavor components that may have presented themselves in rye whiskeys of various ages (peppery notes, cough syrupy favors, etc.) could be removed by heating the vatted whiskeys to specific temperatures. Volatile compounds would dissipate, and the whiskeys will co-mingle to become an entirely new product. These blenders were purposefully using chemistry to create their proprietary rye whiskeys. It may seem like a strange approach to blending because it differs so much from what we consider to be normal today, but these methods were well understood and commonly used by blending houses before Prohibition. And it didn’t stop there…

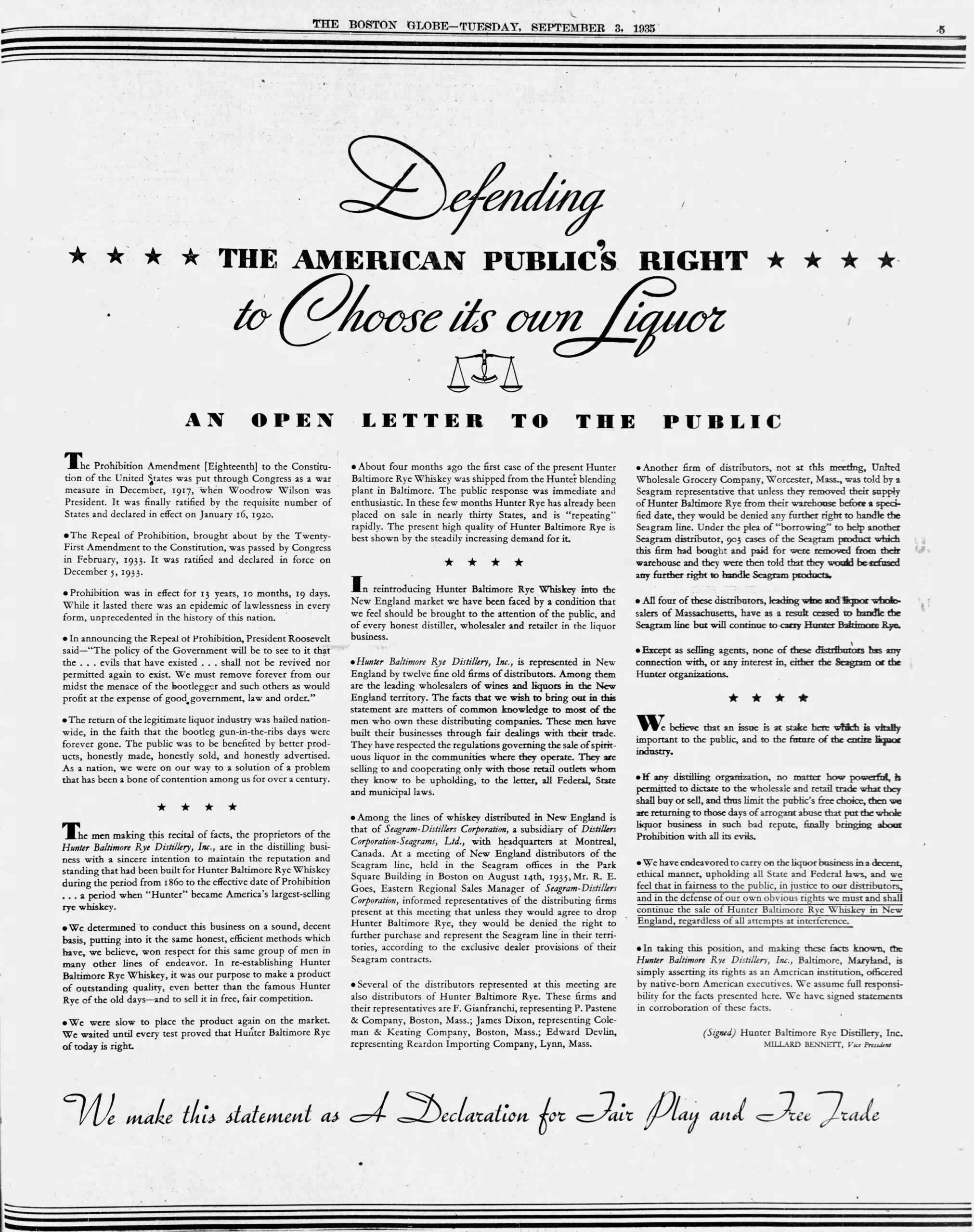

After Prohibition, many old rectifying traditions were embraced by large companies (as if they were new again) to gain a competitive edge for their products. Seagram’s openly advertised their use of heat, agitation, and pressure in their creation of blended whiskeys. This process likely helped to remove unwanted flavors from the young spirits, add the illusion of age, and balance the spirit. Companies like Seagram’s often boasted their use of science over tradition and did not shy away from their desire to blend and rectify. The big difference with Seagram’s AFTER Prohibition is that they were relying on rectification to improve what they knew to be inferior products. It was no secret that neutral grain spirits could not compete with straight, barrel aged whiskeys. We can be sure that they were aware of this drop in quality (and did it anyway) because these companies worked so hard to explain that the quality of their whiskeys were superior to others when the percentages of aged spirits they were using were higher. The pre-Prohibition days of blending 10-year-old pure rye whiskeys together through heat and agitation, however, were long gone. The company that directly advertised their use of “pressure, heat, and agitation” was Schenley. Schenley’s “Black Label” and “Red Label” blends were touted for their use of “flavor-plus Super-Blending” technology in achieving fuller flavors and sealing in “subtle savors.”

The pressure mechanism they were describing was likely an apparatus known as a “sohxlet extractor.” This mechanism was a way to pass the alcohol vapors of blended (aged and new-make) distillate through a kind of gin basket that would have contained toasted or charred wood chips (instead of botanicals as with a gin basket) without re-distilling or soaking the distillate in charred or flavored wood chips. The vapors would simply be refluxed back into the tank once they interacted with the wood, giving it an “additionally aged” quality without having to put it back into barrels for secondary aging.

It would be an incredible experiment to see modern distillers attempt these pre-Prohibition processes. This was not what we think of today as “speed aging” of whiskeys. There were no wood chips or flavor additives placed into the barrels or tanks as you see today. A sohxlet is not what you see used by companies like TerrePure. Besides, that apparatus was likely not employed before Prohibition. It certainly wasn’t necessary because rye whiskey was aged in heated warehouses and there would have already been plenty of wood influence on the whiskeys used in those blends. The practice of heating with agitation was honed over decades of industry experience and the men that employed these techniques understood their applications well. Time, heat, evaporation (of water or alcohols), and agitation were powerful tools in crafting proprietary whiskey blends.

If anything, perhaps my sharing these bits of historic information might help us to realize that we still have a long way to go to understand all that can be accomplished if we step outside of the box. I spoke with Alan Bishop yesterday about these techniques and he was very helpful in explaining how these processes can and do work. I hope one day to discuss the topic with master blenders from Europe as well as some of our very talented blenders here in the United States. Until then, let’s try to remember how much we still have to learn (or re-learn as the case may be)…