Cigars and whiskey go so well together…

They have a lot more in common then how well they pair together…

Whiskey production goes through many stages of development. Malting, milling, mashing, fermenting, distilling and aging.

Tobacco goes through similar processes as well. Harvesting, curing, fermenting, aging, blending and rolling.

Whiskey grains need to malted, which is the process of tricking a seed into waking up and activating its enzymes that will break carbohydrates in the seed down into sugars. Tobacco, when it is dried, or cured, the leaf loses moisture and releases its natural sugars.

Whiskey grains then are ground and cooked at specific temperatures to extract soluble sugars from the mash. Tobacco leaves are left to dry naturally in regulated environments of controlled temperature and humidity. After about a month, the leaves are sent to packing houses where they are separated and graded by size, texture and color. Each leaf is now designated as a wrapper, filler or binder, and the leaf is tied together in groups of leaves called “hands.”

The next step after mashing is fermentation. Yeast is pitched into the solution and those sugars are converted into alcohol, carbon dioxide and all sorts of lovely new flavor compounds. In tobacco production, the “hands” are stacked, re-moistened allowed to “sweat”. The tobacco releases ammonia, nicotine, and other byproducts during this process and the heat of the stacks is closely monitored. The stacks of tobacco are “turned” or rotated several times before the process is complete. The leaves are maturing, and the flavors are concentrating as the chemical composition of the leaf is changing. (Some tobacco leaves are double or triple fermented.)

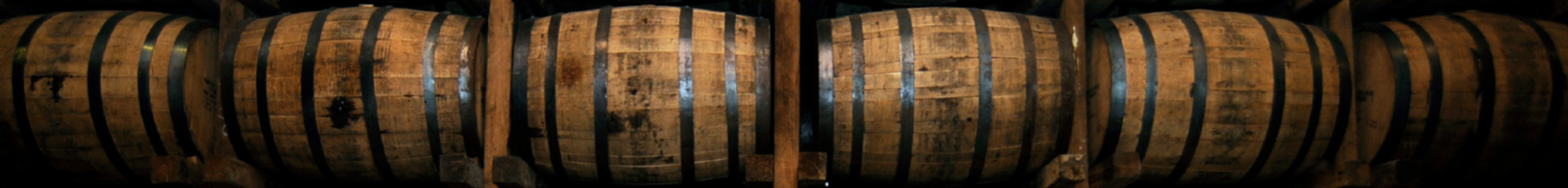

Whiskey is distilled and the finished raw product is then aged in oak barrels. Those barrels are loaded into warehouses and stacked to sit and age for anywhere from 2-12 years (or more). A distillers job includes surveying their vast warehouses and checking the whiskey in these barrels intermittently to determine when it has matured to their liking. After tobacco has been fermented, it is compressed and baled and ready to age. Standard aging can be 18 months to two years, but some manufacturers keep inventories of tobacco as old as 10 years. A cigar maker’s proudest sight is a vast warehouse stacked with aging tobacco bales as far as you can see.

Making a great whiskey can often mean blending different whiskeys together. A master blender will chose each whiskey for its different taste profile, highlighting each whiskey’s strength. A cigar’s actual tobacco blend or recipe is determined by a master blender as well. Each tobacco is selected to create a balanced, harmonious smoke that features a particular taste profile.

Sometimes the best products for our consumption take a great deal of time, effort, and artistry to create. Sometimes, if we’re lucky, we can enjoy those products together. Whiskey and cigars share a lot of parallels both in production methods and taste profile. It’s no wonder they pair so well together…