What is a cooper? Seems there are many children with the name Cooper, but not a whole lot of actual coopers out there.

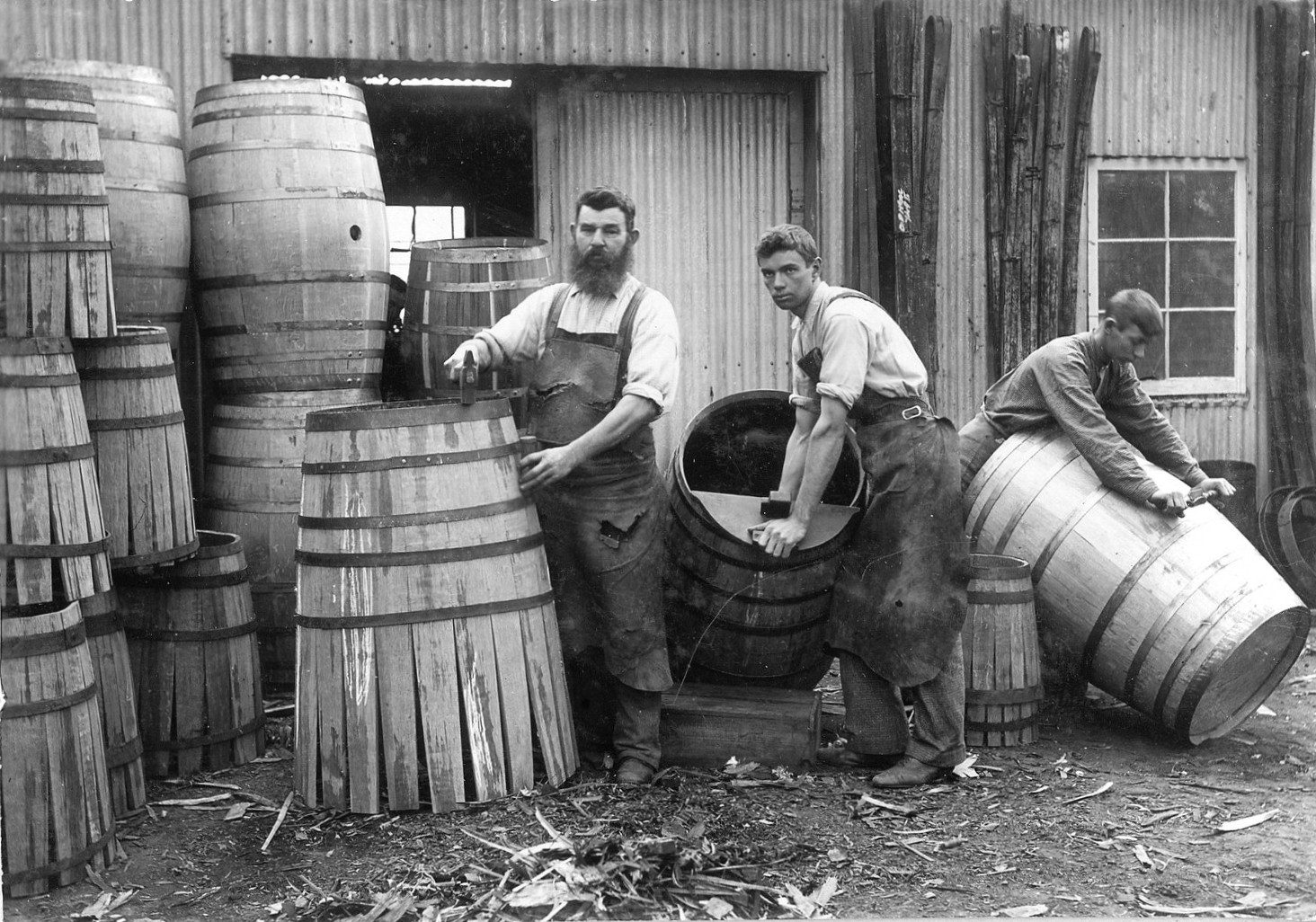

Traditionally, a cooper was the man that made barrels, or staved vessels. A stave is a length of wood, usually cut from the center of a tree trunk, that is cut into a plank (think 1×3”-1×4” wood planks at Home Depot). Anything a cooper produces is referred to as cooperage. The facility where casks or barrels are made is also called a cooperage. The cooperage produced necessary storage vessels for their communities and often the cooper was needed aboard ships and by the military.

A “tight” cooper, historically, made barrels that held liquid. White oak is the only wood that successfully holds water and other liquids due to the living wood’s ability to seal itself from disease, drought and infection with tyloses. Tyloses work like sealants to close off any pores in the cellular structure of the oak. Tight coopers may apprentice for up to 10 years before becoming a master cooper. Their co-workers, or assistants, were often hoopers, which were responsible for binding the staves with galvanized metal hoops. The word barrel designates a size, and coopers were responsible for crafting many sizes and styles of storage and household vessels such as butter churns and tubs. (See my blog on barrel sizes )

A “dry” or “slack” cooper made barrels that held dry goods like grain, hardware and tobacco. A “dry-tight” cooper made barrels that would keep dry goods dry and moisture out. A “general” cooper was the guy on the docks or in the shipping warehouse that was capable of repairing a shipping cask without damaging the contents. He was a very specialized and necessary worker. A “white” cooper produced pails, buckets, churns and dippers usually made of pine or cedar.

Today there are very few coopers capable of hand-making barrels. It is a highly skilled profession and they are in high demand, especially with the barrel shortage that America finds itself in. Most modern coopers work in plastics plants and work with mechanized tools and heavy machinery. The tools of the trade haven’t changed much in hundreds of years. If it ain’t broke…, right? Traditional coopers tools are deceptively simple and incredibly sharp. The level of precision required to form a stave that is meant to fit on an exact angle with all the staves being different widths and tapered into a perfect round form is a little daunting when you actually think about it. Seeing it done is amazing. (watch it here) Unfortunately, like most necessary skills that have been perfected by craftsmen throughout history, coopers have largely become relics.

You can see original tools used by coopers and made in Philadelphia, Pa by John Stortz & Sons, a fifth generation family of tool makers, at the American Whiskey Convention on March 25th at Citizens Bank Park. They will present their cooper’s tools that were made by their family for coopers in Philadelphia during the 19th and 20th centuries. Tickets are available at www.americanwhiskeyconvention.com.